Wholesale Cabinets & Custom Cabinetry Manufacturer

KBM Home crafts premium, custom cabinets for kitchens, bathrooms, bedrooms,living room,balcony and more. Discover our wide range of materials and finishes to find the perfect cabinetry solution tailored to your project.

Get Free QuotesSustainable & Eco-Friendly Cabinets | KBM Home

KBM Home is committed to environmental responsibility of continuously improving the environmental standards of our products. We meet the needs of customers from different countries and regions, match different environmentally friendly materials for your use space, and provide different environmentally friendly products.

FSC Certified

We source our wood from responsibly managed forests, ensuring sustainable forestry practices and minimizing our impact on the environment.

Low-VOC Finishes

Our cabinets are finished with low-VOC or water-based coatings, reducing harmful emissions and promoting healthier indoor air quality for your home.

E1 Grade Materials

We use E1-level wood materials that meet stringent standards for low formaldehyde emissions, ensuring the safety and well-being of your family. The density is about 730kg/m³.

Sustainable Design

Our cabinet designs prioritize space optimization and ease of disassembly and recycling, contributing to a more sustainable future.

cabinets solutions for the Entire house

Global Cabinet Projects | KBM Home

Learn more about KBM Home's custom cabinet features,buy one set kitchen cabinet,bathroom vanity and wardrobe for your house.You will find that through collaborative design, fiction can be turned into reality, and reality can be made more practical. The perfect installation effect of the product makes the overall space more beautiful, which is the charm of KBM home whole house customization.

KBM Home

17 years of experience Cabinet Manufacturer

KBM Home offers comprehensive home interior solutions, including custom design, R&D,manufacturing, home renovation, and installation services for Global partners .Provide one-stop, personalized "whole house customization" services for our clients (design companies, hotel engineering, apartment projects, office buildings, villas, home decoration residences). Our business covers the whole world, including measurement, design solutions, distribution, installation, and after-sales service. Our direction is to establish long-term cooperation and development with partners, learn more experience through transactions, and transform it into better quality services.

17+

Years Exporting Experience

350+

Employees

42K+

Projects

28K ㎡+

Factory Plant

KBM Home Cabinetry Advantage

Expert Team & Service

KBM Home's team of experienced designers, engineers, and project managers are dedicated to providing exceptional customer service and support throughout your cabinetry project.

Advanced Manufacturing

We utilize state-of-the-art German HOMAG technology and data-driven processes to ensure precision, efficiency, and superior quality in every cabinetry project & custom cabinets.

Quality Assurance & Certifications

KBM Home is committed to delivering the highest quality cabinetry products. We hold ISO certification and adhere to rigorous quality control standards, ensuring your satisfaction.

Unparalleled Quality & Craftsmanship

We use only premium materials with superior quality and skilled craftsmen to create cabinetry that is both beautiful and built to last.

Competitive Pricing & Value

KBM Home offers competitive pricing without compromising on quality. Our efficient manufacturing processes and commitment to value engineering ensure you receive the best possible return on your investment.

Tailor-Made Cabinetry Solutions

We specialize in creating bespoke cabinetry solutions that are tailored to your unique needs and preferences. Our design team will collaborate with you to personalize every aspect of your cabinetry project.

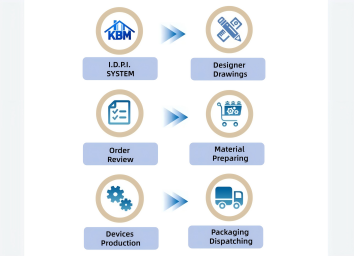

Custom Cabinets Process

CUSTOM CABINET SOLUTIONS

Step 1: Transfers each order’s production data directly to each machine

Step 2: Prepare materials for the board warehouse

Step 3: Transfer to the material preparation area and wait for instructions to be transmitted to the processing equipment.Each board is automatically pasted to every position based on the QR code label generated by the disassembly software

Step 4: The equipment cuts according to instructions

Step 5: Software checks if each board component passes

Step 6: Classify and stack

Step 7: Complete the order, place it in the designated location, and wait for the next process

CUSTOM CABINET SOLUTIONS

Step 8: The board undergoes edge sealing treatment to completely seal the exposed material

Step 9: Intelligent drilling, intelligent sorting and inspection, workers only need to scan the QR code on each panel. The system then guides the machine to automatically drill precise holes.

Step 10: Transmit to our intelligent sorting system to track and verify every item, ensuring that no parts are lost. This is very important to track the whereabouts of each order and even each board in the workshop through ERP software. At the same time, during the sorting process, the quality of the boards is manually identified and each unit cabinet is classified into different designated locations. We have a large display screen for real-time monitoring. This is our production management system

CUSTOM CABINET SOLUTIONS

Step 11: Packaging Quality Inspection Procedure After intelligent sorting, the final inspection personnel carry out refined inspections (cleaning the hygiene of each board), which can effectively detect problems that the equipment cannot detect (such as color problems, quality problems, etc.). If any problems are found, the QR code label data can be promptly and effectively remade to ensure that defective products do not flow out to customers.

Step 12: Using the ERP system, scan the QR code of each panel to confirm the correct quantity and accurately match the order, transmit the data to the database, and seamlessly integrate the office and workshop for data synchronization and clear understanding of the completion status. This is our production management system.

CUSTOM CABINET SOLUTIONS

Step 13: According to customer requirements, paper packaging and wooden box packaging are completed and stored in the corresponding warehouse of the intelligent warehouse. It should be noted that entering the large warehouse requires scanning a QR code or ID card to allocate storage positions. The storage period varies, ensuring that the products will not deteriorate and are easy to find. At this time, the intelligent ERP system is applied for classification. Store (boards, commonly used hardware, functional hardware, etc.) separately in different storage locations. This is our production management system

Cabinet Quality Control System

KBM Home, When the industry emerged 15 years ago, it was a small-scale factory with only one production line and 500 square meters area. By continuously attracting talent, investing the developed funds in advanced equipment, and then transforming to a scale of 10 lines online and offline due to the disruptive demand for intelligent production in the industry. We have been involved in research and development, as well as system improvement, with the aim of converting orders into standardized or customized products. In order to serve every customers, we have developed from domestic sales to global sales through quality and service control. Our mission needs to continue, to continue learning, to replace better equipment, and to use more advanced management systems. This is the significance of our KBM Home's refined production management.